BACKGROUND

We all know that water may often contain toxic substances and various unwanted organic compounds, making purification a necessity.

Common purification methods include:

a) Sonication: Using high-frequency sound waves to separate impurities.

b) Hydrodynamic cavitation: a phenomenon that occurs when a liquid flows through a constriction such as a nozzle, venturi, or orifice, causing a sudden drop in pressure that forms vapor bubbles. These bubbles collapse downstream, releasing intense energy in the form of shock waves, high temperatures, and micro-jets which in turn kill germs, break down pollutants, and generate powerful cleaning reactions.

c) The use of chemical catalysts : using substances that increase the rate of a chemical reaction without being consumed or permanently altered in the process, like charcoal.

However, these methods often yield limited results. For example, when using chemical catalysts, only a fraction of the unwanted compounds may be removed.

The Fluid Decontamination Apparatus (PATENT NUMBER – US 12344535 B2) is designed to overcome the limitations of such conventional methods.

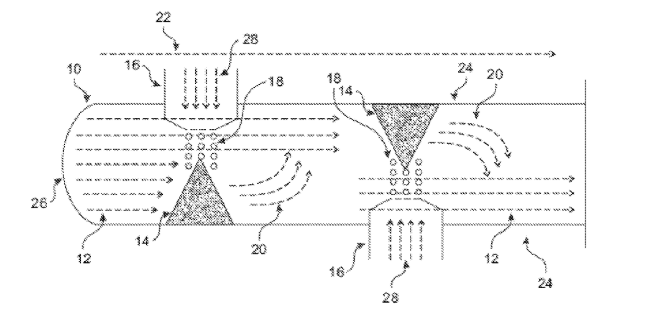

As the incoming fluid comes into contact with the substrate from all directions, it undergoes chemical reactions that facilitate decontamination. By modifications in the 3DOS substrates and nozzles, this process of decontamination also integrates hydrodynamic cavitation and the use of chemical catalysts. Such a combined approach significantly increases purification efficiency.

THE INVENTION

The apparatus consists of one or more three dimensionally open-structured (3DOS) substrates (filtration material) with a network of interconnected pores or voids, allowing fluids to flow through them easily.

When contaminated fluid is introduced through one or more nozzles, it is made contact with 3DOS before discharging via an outlet. These 3DOS are porous and permeable and made of metal alloy (metal foam- FeCralloy) and can be coated with chemical catalysts to enhance the ability of purification through chemical reactions.

Such metal surfaces of the 3DOS can be smooth, corrugated, or even made from fine wire meshes arranged inside the chamber, ensuring that the water has maximum contact with the reactive surface, leading to better cleaning results.The 3DOS substrates further provide active sites on its exterior and/or interior surfaces wherein chemical reactions can proceed also.

A similar effect can also be achieved with 3DOS substrates comprising of corrugated and/or smooth metal strips and also 3DOS substrates with wire mesh wound in a cylinder or placed as a packed bed within a container body, will also give the same effect.

The fluid cleaning device can also be combined with a special UV light chamber, where the dirty fluid passes through and gets disinfected using germ-killing ultraviolet (UV) rays. This chamber is usually made with quartz walls, which let the UV light pass through easily and reach the fluid. The reactor chamber is preferably constructed with quartz walls, allowing UV light to effectively penetrate and impinge upon the fluid.

To further enhance the decontamination process, the apparatus can also include 3DOS substrates made of quartz material, which also permit the transmission of UV light. These substrates may be configured as a packed bed of quartz beads or particles, or as a structure comprising quartz particles fused onto quartz support struts, which will help to spread out the fluid and increase the amount of it that gets hit by the UV light while it moves around quickly, which makes the disinfection process faster and more effective.

All these designs ensure that the water has maximum contact with the reactive surface, leading to better cleaning results.

ADVANTAGES

a) Nozzles can be installed into inlet openings on the apparatus body and are engineered to inject the fluid—with or without air—to generate hydrodynamic cavitation.

b) With 3DOS substrates that are both porous and permeable, the fluid are able to pass through the apparatus, while maintaining turbulent and cavitation-inducing flow conditions. This extended interaction significantly increases the fluid’s exposure to decontaminating forces

c) Furthermore, these substrates can be coated with catalytic materials, enabling targeted chemical reactions as the contaminated fluid comes into contact with the porous surfaces.

These combined mechanical and chemical actions result in the effective degradation and transformation of toxic substances and organic pollutants, thereby substantially improving the overall efficiency and performance of the decontamination process.

Author: Bhuvanya Sureshkumar, Legal Intern at PA Legal

Thank you for reading our blog! We’d love to hear from you!

- Are you Interested in IP facts?

- Would you like to know more about how IP affects everyday lives?

- Have any questions or topics you’d like us to cover?

Send us your thoughts at info@thepalaw.com. We’d love to hear your thoughts!