BACKGROUND

Fruits are a vital component of the human diet, providing essential vitamins, dietary fibers, and phytochemicals that support overall health, strengthen immunity, and help reduce the risk of chronic conditions such as diabetes and hypertension.

However, during storage and transportation, fruits are susceptible to mechanical damage from collisions and spoilage due to microbial contamination, both of which negatively affect their flavor, taste, and market value.

To address these issues, anti-collision and fresh-keeping fruit packaging solutions have been developed.

1. One such solution involves using a transparent bag made from a material of specific thickness with a porous structure designed to cushion the fruit. While this helps reduce mechanical damage, the porous nature of the material makes it vulnerable to contamination by external microorganisms, ultimately compromising the fruit’s freshness.

2. Another approach involves an inflatable film bag specifically designed for fruits like peaches, where air is used within the packaging to absorb impact. Although effective to some extent, this method suffers from a bulky design, complicated manufacturing, and high production costs, making it unsuitable for widespread commercial use. Additionally, such materials are not biodegradable, posing environmental concerns.

Meanwhile probiotics, which are live microorganisms known to support human health by improving gut function, aiding metabolism, promoting skin health, and providing other benefits; are rarely explored in the context of food packaging. Despite their proven value in nutrition and health, their integration into fruit packaging remains largely untapped.

Considering this in mind, this US patent (PATENT NUMBER – US 12344764) brings in a method for preparing an antibacterial and fresh-keeping fruit-packaging material through three-dimensional (3D) printing.

ABOUT THE INVENTION

This method involves several key steps.

1. First gum arabic (a natural, water-soluble gum from Acacia trees) and pullulan (a naturally produced carbohydrate/layer of sugar synthesized by the fungus Aureobasidium pullulans) are separately dissolved in deionized water to form individual solutions.

2. Along with this, a probiotic strain is cultivated, centrifuged, and resuspended to obtain a bacterial suspension. The probiotic is selected from the group consisting of Lactobacillus acidophilus, Lactobacillus casei, Bifidobacterium thermophilum, and Lactobacillus bulgaricus.

3. These three components i.e.the gum arabic solution, pullulan solution, and bacterial suspension, are then mixed to create a core layer solution.

4. In parallel, a shell layer solution is prepared by mixing polyvinyl chloride (PVC) with a modifier and a plasticizer.

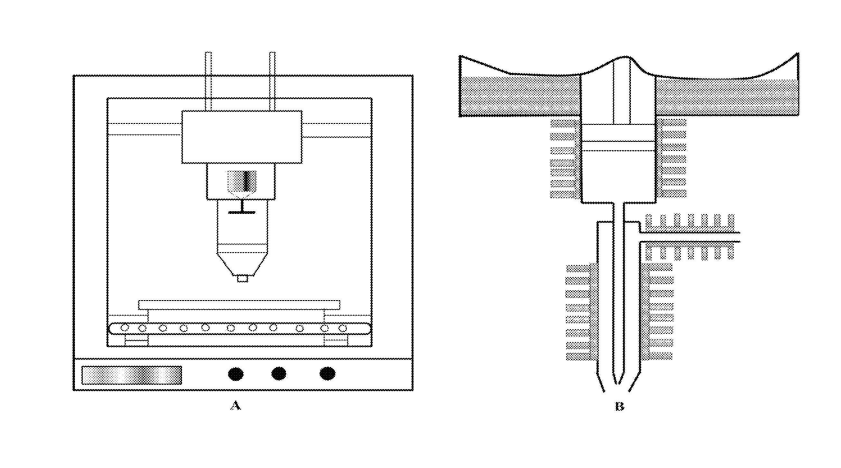

5. The core and shell solutions are then loaded into separate syringes and subjected to coaxial 3D printing, resulting in a material with a core-shell structure.

6. To enhance the packaging’s strength and functionality, an outer layer is formed by performing uniaxial 3D printing using only the shell layer solution.

The final product is a layered fruit-packaging material that incorporates probiotics and is designed to inhibit bacterial growth while extending the freshness of the packaged fruit.

In short a 3D-printed packaging material with an inner layer for fresh-keeping and an outer layer for protection.

ADVANTAGES

1. Probiotic is used in this fruit packing material which makes a positive impact on the host body by promoting gut health and preventing diseases like constipation and diarrhea.

2. Since the antibacterial agents come directly into contact with the fruit, the preservation effect is significantly enhanced without any harm to human health.

3. The outer shell layer, made of modified PVC, features adjustable hardness and durability, allowing it to withstand mechanical damage during storage and transport.

4. The shell is printed in a shape tailored to fit the fruit, and an additional anti-collision layer is applied using uniaxial 3D printing to further strengthen protection. Such packaging material offers a dual function:

a) the inner layer with probiotics extends shelf life by preventing spoilage,

b) while the outer modified PVC layer protects against mechanical damage. In addition, the designed packaging material is safe and non-toxic, and can be in direct contact with a food.

Conclusion:

Sometimes the solution isn’t about inventing something entirely new, but about looking at existing materials in a different way and using them in novel ways. This innovative packaging, integrating existing probiotics with three dimensional printing, can actively preserve freshness and reduce spoilage more effectively than existing options.

Author: Bhuvanya Sureshkumar, Legal Intern at PA Legal

Thank you for reading our blog! We’d love to hear from you!

- Are you Interested in IP facts?

- Would you like to know more about how IP affects everyday lives?

- Have any questions or topics you’d like us to cover?

Send us your thoughts at info@thepalaw.com. We’d love to hear your thoughts!